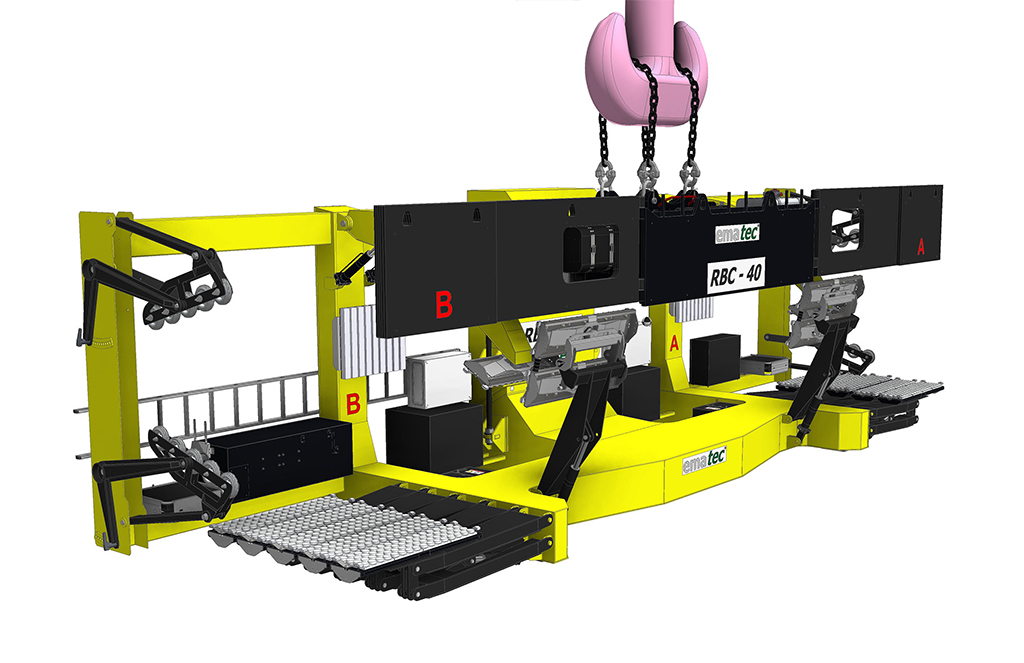

100 percent of green electricity, even right from the assembly of wind turbines: The Bavarian specialist supplier Ematec, based in Memmingerberg near Memmingen, now also offers its rotor blade lifters RBT, RBC and EMT in the ecological GreenLine version. The Ematec GreenLine high-end battery drive emits no emissions, operates almost in silence and is thus perfect for use in the wind energy industry. Ematec GreenLine can be used in all countries and wind turbine manufacturers may bypass the many different emission regulations that exist worldwide.

“It is just a perfect match: an emission-free rotor blade installation for regenerative energy. There is an enormous potential. Above all, with our new drive, we do not only offer a particularly ecological solution, but also a technology that is fit for the future which saves wind turbine manufacturers a lot of trouble in complying with the various emission regulations – whether in China, the EU or the US” emphasizes Manfred Eberhard, CEO of Ematec AG.

By using an emission-free drive for the rotor blade installation in the onshore and offshore sector, Ematec GreenLine can be used in all countries. Emission limits such as the stricter emission regulations according to the Euro 5 standard, which have been in effect since 1st January 2019, or the different tier classifications are no longer a problem with Ematec GreenLine. In addition, Ematec deliberately kept the electric motor below 48 volts, which allows being used in the US and meets the requirements of the UL (Underwriters Laboratories).

The high-end battery drive is not only especially ecological, but also particularly powerful and generously dimensioned. Even at temperatures down to -20 degrees Celsius, the battery allows a working time of more than 16 hours thus being able to install three rotor blades in one day. With a maximum charging time of 2.5 hours, even an empty battery is quickly ready to be used again; with a charger being integrated. Ematec GreenLine works very efficiently and is only active when movements on the rotor blade lifter are required. The remaining time the Power Pac is in sleep mode and noiseless.

Ematec GreenLine works energetically in a completely self-sufficient and decentralized way, as every main assembly of the traverse, for example the gripper units on the left and on the right, is equipped with its own Power Pac. A redundant supply and drive guarantee high availability. The electro-hydraulic unit enthuses with low operating and maintenance costs and a long battery life of up to eight years. Another advantage: the GreenLine version costs no more than the conventional technology with an internal combustion engine.