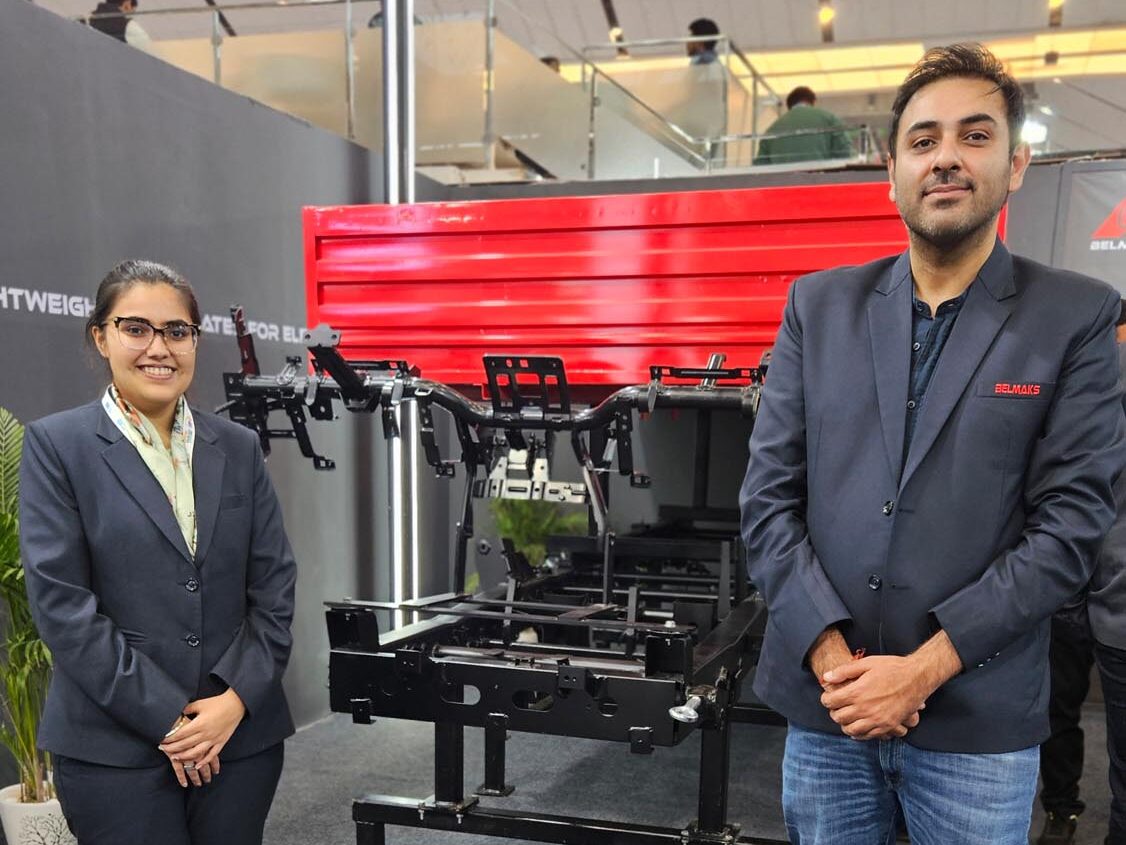

Belmaks, a leading manufacturer of commercial vehicle components, made a strong impact at the Bharat Mobility Global Expo 2025 by showcasing its latest advancements in light-weighting solutions for Electric Vehicles. Giving an exclusive walkthrough of the company’s stand to MOTORINDIA, Raahil Bhatia, Director of Belmaks, outlined the company’s extensive product range and its commitment to delivering innovative solutions to commercial vehicle and off-highway vehicle OEMs.

Diverse Product Portfolio and Advanced Manufacturing Capabilities

Belmaks operates across five primary product categories:

- Chassis – Complete Chassis frames and under-body assemblies is the core business vertical of Belmaks. With a massive production capacity of 100,000 chassis frames per year, the company is a major supplier to truck & bus OEMs in India and globally. Notably, the company has launched a tubular chassis for Electric Trucks, marking a major milestone in its product evolution.

- Superstructures – Belmaks is well-positioned as a strategic Applications partner to OEMs with large-scale and world-class manufacturing setups for Tippers, Cargo-bodies, Containers and Special Applications. Additionally, the company has entered heavy-duty Mining Tippers, leveraging its expertise in high-strength and hard materials.

- Cabin Parts – The company manufactures a range of cabin components, including the front fascia, cross-car beams, stampings, grills and bumpers. With advanced robotic hemming, welding, stamping and multiple CED-coating lines, Belmaks ensures precision engineering while maintaining aesthetic integrity.

- Heavy Fabrications –The company holds a reputation for making some of the largest and most complex heavy fabrications with tight tolerances for off-highway vehicles in India and globally.

- Fasteners – Belmaks offers a wide range of nuts, bolts, rivets, screws and special fasteners to OEMs from its integrated facility at Faridabad.

Innovation in Light-weighting and Electric Mobility

A major highlight of Belmaks’ showcase was its electric truck chassis, which significantly reduces vehicle weight by 40-50 kilograms, thereby enhancing vehicle efficiency and extending driving range. “As the cargo body and chassis are the heaviest components in a vehicle, our goal is to be a complete light-weighting partner to EV OEMs,” Bhatia stated. Belmaks has developed a boutique of innovative light-weighting solutions for both these aggregates. “We strive to be a 1-stop shop, providing complete solutions- from customised designs, in-house tooling & rapid prototyping to setting up high-capacity production lines next-door to our customers,” said Bhatia.

A Legacy of Excellence and Global Expansion

Founded 60 years ago, Belmaks has built a strong legacy in the commercial vehicle industry. “For six decades, we have been serving our customers, and we hope to continue doing so for the next sixty years and beyond,” said Bhatia. With a 2,000-strong workforce, the company is dedicated to customer satisfaction.

Belmaks has nine manufacturing plants in India, strategically located adjacent to OEM facilities, enabling seamless just-in-time (JIT) and just-in-sequence (JIS) delivery models. This proximity ensures faster response times and optimized supply chain efficiencies. Belmaks prides itself on maintaining world-class quality standards and robust systems, holding 5 different ISO certifications. Belmaks is also expanding globally, exporting to Asia, Europe, and North America, with South America set to be its next target market.

Expanding Beyond Components to Full Assembly Solutions

Beyond component manufacturing, Belmaks is transforming its business model to become an end-to-end aggregate supplier. The company manufactures complex stampings and fabrications, integrates proprietary parts, and delivers completely-assembled and ready-to-fit solutions directly to OEM production lines from its next-door ancillaries.

Sustainability at the Core of Belmaks’ Vision

Belmaks has set ambitious sustainability goals, aiming to become carbon neutral (Scope 1 & 2) by 2030, with Scope 3 emissions targeted by 2040. For its flagship plant in Indore and new plants in Alwar and Bangalore, the target for Scope 1 & 2 is as early as 2028 and the company is putting organised efforts and resources to achieve this.

To meet these objectives, Belmaks is investing in circular economy initiatives, recycling projects, and innovative energy solutions. “Sustainability is at the heart of everything we do, and we are going all out as a team to achieve our goals,” Bhatia emphasized.

With a robust product portfolio, cutting-edge manufacturing capabilities, and a clear commitment to sustainability, Belmaks is poised to lead the commercial vehicle industry into the future.