Schuler has acquired the Italian mechanical engineering firm Sovema Group to become a leading systems supplier of battery cell manufacturing solutions for the automotive industry and other sectors. Together with Sovema, Schuler will develop the capabilities needed to equip gigafactories for the mass production of lithium-ion batteries, whose large-scale availability is essential for the success of eco-friendly e-mobility on the road.

According to estimates, the production capacity provided by the annual output of lithium-ion batteries will increase approximately fivefold worldwide by 2030, compared with 2020. One third of the planned capacity is expected to be produced in Europe. In addition to Germany, there are plans to build new gigafactories in Italy, Spain, France, the UK, Sweden, Finland, Poland, and Hungary.

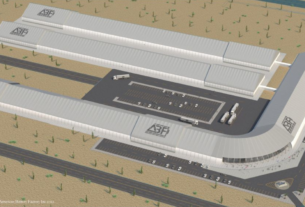

Based in Villafranca di Verona, Italy, with further sites in the USA and China, Sovema is one of the leading international suppliers of equipment for the production of top-quality battery cells. The company made a name for itself in the automotive sector as well as other industries by building appropriate machines for pilot and laboratory projects, accounting some of the most prominent battery manufacturers worldwide in its customer portfolio. Furthermore, Sovema is the worldwide-only supplier of automated turnkey plants for the mass production of lead-acid batteries. The Sovema Group employs just over 170 people and most recently reported sales of around 50 million euros.

“With Schuler as owner, we can now combine Sovema’s technological expertise with our know-how in the production of complex lines for the – mass manufacturing of parts and components,” states Schuler CEO Domenico Iacovelli. “This gives us the potential to develop Schuler into a turnkey supplier of technology for the core process steps of cell assembly and cell formation for existing or planned gigafactories dedicated to manufacturing lithium-ion battery cells.”

“We see the entrance of Schuler as new owner as a great opportunity for Sovema to unfold all its technological potential and play a major role in the gigafactory challenge,” states General Manager Massimiliano Ianniello. “So far, our size allowed us to serve our customers with high quality and customization. Now as part of Schuler Group we will finally be able to reach the volumes required by the massive demand for battery manufacturing equipment in Europe and beyond.”

Schuler already offers production lines for the cost-efficient mass manufacturing of both prismatic and cylindrical battery cell housings.

The lithium-ion cell is the core of the battery packs installed on electric vehicles, and defines their performance in terms of energy density, charging/discharging capability, and lifetime. Currently, there are three main cell formats on the market: cylindrical, pouch, and prismatic. The first process step in the assembly of cylindrical battery cells is winding, in which the anode and cathode foils – separated from each other by separator foils – are laid on top of each other and wound. This is also known as “jelly roll”. In the case of pouch cells, anode and cathode foils are first separated and then stacked in a repeating cycle of anode, separator, cathode, separator, and so on. Prismatic cells can be assembled using both processes. After the current collector foils are contacted with the cell tabs, the jelly roll or stack is placed in the cell case and then filled with the electrolyte.

Formation describes the initial charging and discharging processes of the battery cell. During this process, a solid electrolyte interface (SEI) is formed at the anode, which is necessary for the functionality of the battery cell. The process takes up to 24 hours and leads to a discharge of gas. After degassing, the cell is sealed. The final process step is aging: the cells are stored on high shelves for up to three weeks in order to detect short circuits and check the cell characteristics and cell performance. If the cell properties no longer change during this period, production is complete. End of line tests are required at this stage to certify the compliance of the cells before they are assembled into modules and then packs.

The Sovema Group has expertise in the cell assembly and formation from the electrode shaping to the finished cell, with specific skills both in the automation of the process and in the power electronics used for formation and testing. Sovema was founded in 1969 as a division of the lead-acid battery manufacturer Uranio, based in Verona, Italy, and has been independent since 1992. This was followed in 2011 by the formation of the Solith division for the production of cells and modules for lithium-ion batteries, and the two power electronics brands for battery formation and testing (Sovel and Bitrode). Today, the company also has facilities in St. Louis (Missouri, USA) and Tianjin (China).