With innovative joining technologies and a broad expertise in battery assembly, Atlas Copco is an ideal strategic partner for electromobility.

The assembly process of a high voltage EV battery pack has a strong impact on the performance, safety and durability of the battery. Choosing the right joining technology, as the special prerequisites of battery manufacturing demands, and aiming for an efficient joining process is crucial.

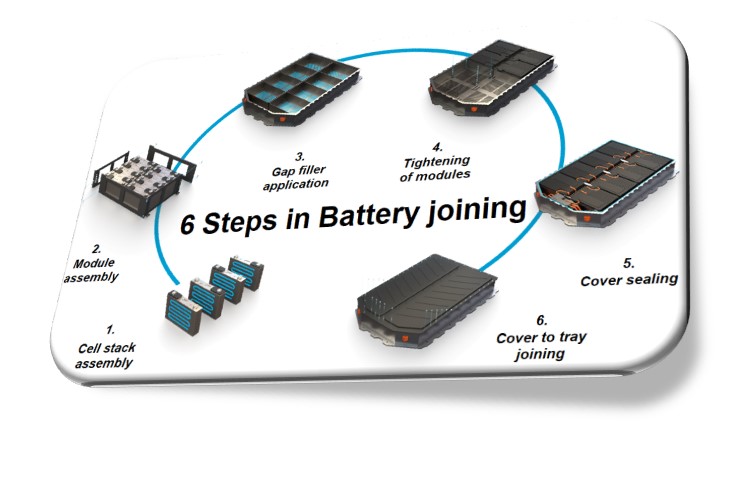

Following is a six-step process for assembly of an incomparable EV battery pack:

1. Cell-to-cell bonding: Bubble free result is a safety issue

To supply the required energy, prismatic battery cells must be firmly attached to cell stacks. This is a major challenge, because the cells are quite delicate. No heat or force can be applied in the joining process.

By using 2C adhesive bonding, no external heat is required for the hardening, and the joint meets the highest demands in terms of rigidity and crash behavior. With the use of light elastic adhesives, vibrations are absorbed during operation, which increases battery lifetime. This also allows the cells to expand slightly while charging and discharging. The adhesive application must be precise and reliable to avoid air pockets. This is crucial for full contact and insulation. In case of a crash, air pockets can lead to short circuits – a huge safety issue in high voltage systems.

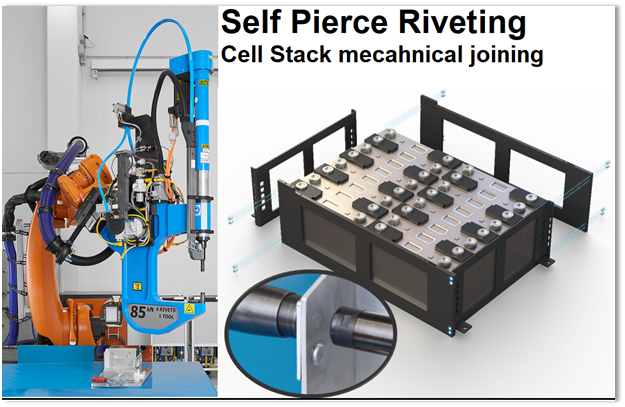

2. Reinforcement of cell stacks: Cold joining is required

To protect the battery in case of a crash, cell stacks can be reinforced with lateral braces. Common joining techniques like spot welding are not suitable for this assembly step, because they create heat and welding splatter that can harm the sensitive cells.

The solution is a cold joining technique such as self-pierce riveting. This clean and purely mechanical joining process brings no heat into the cells and does not generate any hazardous vapors or weld spatters. Self-pierce riveting can join multiple layers of different materials such as aluminum or steel, providing electrical conductivity for grounding. The joining process is highly reliable with short cycle times. This enables design freedom and maximum safety while keeping productivity at a high level.

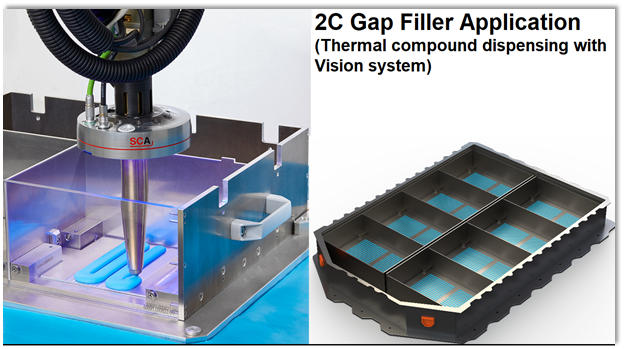

3. Gap filler: Dispensing the thermal-conductivity paste is a challenge

A huge challenge in battery manufacturing is temperature management. Battery cells must be operated within a specific temperature range to preserve their performance and avoid overheating. For this reason, a heat-conducting paste is applied. But to guarantee thermal conductivity, a bubble free result is crucial. This is a challenge, because the liquid gap filler material is applied at high volumes. It requires precise metering technology. Additional monitoring features can be an advantage. Laser or camera-based systems for example monitor the position of the bead to ensure a precise result. Application errors are recognized and can be corrected immediately. This keeps the cycle time short and reduces the costs of rework or quality assurance.

It must also be considered that the gap filler materials are highly abrasive and may quickly wear out the dispensing equipment. The system components, such as material supply and meters, must be designed to handle high volumes of challenging materials at a high productivity level.

4. Module mounting: Soft joints need controlled tightening

The battery modules need to be mounted on top of the liquid gap filler paste at the bottom of the tray. This can be done with tightening. But the soft joint behavior of the gap filler is challenging. The paste gets squeezed out easily or air inclusions remain.

To guarantee even distribution and full contact between the battery modules and the thermal compound, the tightening process needs to be fully controllable. An electronically controlled multi-spindle solution is recommended to achieve an even tightening process. By working synchronously in the final tightening the cycle time is reduced and each module is fixed evenly in the tray. The programmed tightening strategy needs to consider the behavior of the liquid conducting paste to create optimal contact.

5. Cover Sealing: Protection against moisture and gases is crucial

Once all modules are tightly fixed, and the battery management system is installed, the tray must be sealed. It is crucial to avoid any penetration of moisture, otherwise the battery power deteriorates dramatically and it can lead to damage and corrosion. Furthermore, the battery produces hazardous gases that can be harmful for the passengers. The internal space must be sealed completely from the inside and the outside.

For this, a precise and uninterrupted sealing application is vital. This can be done either on the cover or on the tray. Since the battery cannot be exposed to heat, materials such as 1C hot butyl, 2C polyurethane or 2C silicone are suitable. They require no oven curing. Hot butyl is also removable for service works. Regardless of the material, the application needs to be uniform, and it is particularly important that the beginning and end of the bead are precisely placed to ensure a tight seal.

6. Cover to tray joining: Serviceability calls for reversible joining

Finally, the cover is mounted on the housing. At this stage the housing is only accessible from the outside and this needs to be considered when choosing the joining technology. This bond should also be detachable to facilitate maintenance and dismantling.

Flow drill fastening technology meets these requirements perfectly. The screw is rotated at high speed and pressure to warm up the material. This allows the fastener to push through the material stack, cutting the thread in the process – an efficient and flexible joining technology for multi-material stacks. The process provides reliable mechanical bonding, is reversible and requires only one-sided access. No surface preparation is needed. The metallic components are thus in a conductive bond and form a Faraday cage, which prevents electromagnetic interference.