With the development of innovative and recyclable battery cells and near-standard production of cell prototypes at its new pilot plant, the BMW Group has set itself the goal of creating a closed and sustainable material cycle for battery cells.

Sustainability plays a central role in expanding electromobility. The BMW Group has therefore set itself the goal of creating a closed and sustainable material cycle for battery cells. With a new pilot plant that will produce lithium-ion battery cells, the company is taking the next logical step in penetrating all aspects of the battery cell value chain: from selection of materials, to battery cell composition and design, all the way to near-standard production and recycling.

Milan Nedeljković, member of the Board of Management of BMW AG, responsible for Production: “The new pilot plant will strengthen our expertise in production of battery cells. We will be capable of testing new systems technology and innovative production processes. Our goal is to optimise near-standard production of battery cells from the perspective of quality, performance and costs. The new pilot plant will enable us to close the final gap in the value chain from battery cell development, to production of modules and powertrain components, all the way to installation of fully assembled high-voltage batteries at our vehicle plants. This makes us the first car manufacturer to cover the entire process chain for electric driving.”

Frank Weber, member of the Board of Management of BMW AG, responsible for Development: “By 2023, the BMW Group will have 25 electrified models on the roads, as it systematically increases electrification across all brands and model series. This continued expansion and our comprehensive battery cell expertise will give sustainability a major boost. At the same time, our models’ eDrive technology also ensures brand-typical dynamic performance and driving fun.” Weber continued: “We are not just focused on the most efficient battery cell, but on its entire value chain. That is why we are working with our partners to create a closed material cycle for battery cells.”

The pilot plant will be built in Parsdorf, near Munich, and is scheduled to go into service in late 2022. The total project volume is almost 110 million euros and about 50 employees will work at the plant. The German Federal Ministry of Economic Affairs and the Bavarian Ministry of Economic Affairs, Regional Development and Energy is supporting the project within the framework of the European funding process IPCEI (Important Projects of Common European Interest).

Near-series production of battery cells

The company just opened a separate Battery Cell Competence Centre in Munich in November 2019, covering the entire battery cell value chain, from research and development to battery cell composition and design, all the way to large-scale manufacturability.

The BMW Group is taking the next logical step with the new pilot plant and further expanding its expertise. The goal is to enhance battery cells’ performance capabilities and demonstrate large-scale manufacturability. To do so, the BMW Group will develop innovative production processes and systems, which will then be installed at the 14,000 m² pilot plant. Using production processes and systems also employed in standard production, the company will be able to demonstrate the industrial feasibility of future battery cell generations. The main focus will be on optimising production efficiency, costs and quality.

Building on know-how from the Battery Cell Competence Centre and, later, also from the pilot plant, the BMW Group will bring optimal battery cell technology to series maturity within the shortest implementation time possible and enable suppliers for battery cell production to its own specifications. A quarter of BMW Group vehicles sold in Europe should have an electric drive train by 2021; a third in 2025 and half in 2030.

Sustainable battery cell of the future will be recyclable

To make an effective contribution to climate protection, the overall environmental balance of all vehicle components must be improved and partners brought into the process. This applies in particular to energy-intensive production of battery cells for electric vehicles. Up to 40 percent of a fully-electric vehicle’s CO2 emissions come from battery cell production alone.

To develop innovative and sustainable battery cell technology, the BMW Group is working as part of a technology consortium with the Swedish battery manufacturer, Northvolt, and Umicore, a Belgian developer of battery materials. The collaboration is focused on creating an end-to-end sustainable value chain for battery cells in Europe, extending from development to production to recycling.

Northvolt will produce the battery cells at its own gigafactory currently under construction in Skellefteå in northern Sweden from 2024 on. Northvolt will obtain the energy needed to produce the battery cells exclusively from wind and hydroelectric power generated regionally in northern Sweden.

Umicore will contribute to development of a sustainable battery cell in Europe. Recyclable cell design is a consistent focus from the very beginning of battery cell development. Faced with rapidly growing demand for battery cells, recycling of battery components at the end of their lifecycle and extensive reuse of raw materials will be key to closing the materials loop in the best way possible.

Battery cells to be produced with Green power

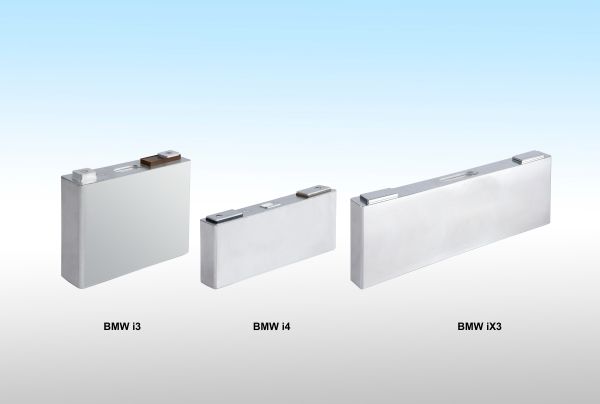

As a leader in sustainability, the BMW Group has already reached a contractual agreement with its cell manufacturers that they will only use green power to produce fifth-generation battery cells. The fifth-generation battery cell will be on the roads later this year in the BMW iX3 and rolled out in more products over the coming year, like the BMW iNEXT and the BMW i4.

As volumes increase, the use of green power will save around ten million tonnes of CO2 over the next ten years. For comparison, that is roughly the amount of CO2 a city of over a million inhabitants, like Munich, emits per year.

The BMW Group has been analysing battery cells since 2008 and, thanks to this long-standing experience, already has extensive knowledge in the field of cell analysis. Through the research conducted by the support programmes, the BMW Group will be able to refine chemical composition, cell mechanics, cell design and the production process down to the last detail. Battery cell manufacturers can build on this know-how and use it in a targeted manner for sustainable and successful industrialisation.