With an aspiration to make the future sustainable for the next generation, Dayco is consistently partnering and delivering its eco-friendly innovations to prominent original equipment (OE) manufacturers. Dayco, a leading engine products and drive systems manufacturer for the automotive, heavy-duty, industrial, and aftermarket segments, is not only known for its strong design capabilities but also is a preferred solution provider for delivering high-tech OE components around the world from its global manufacturing facilities.

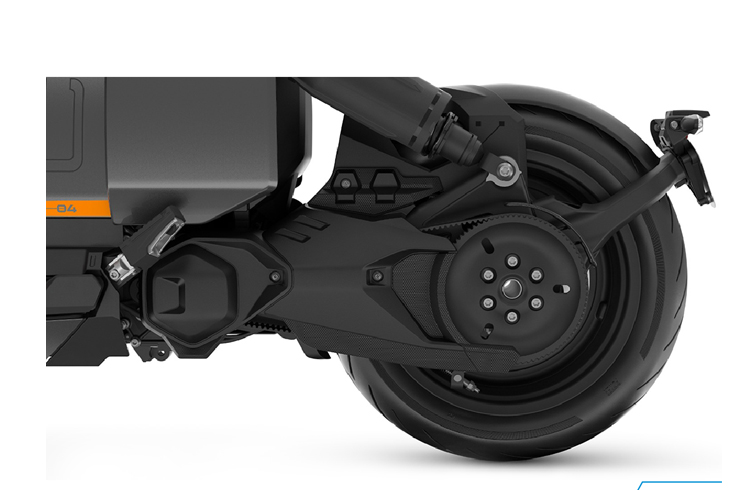

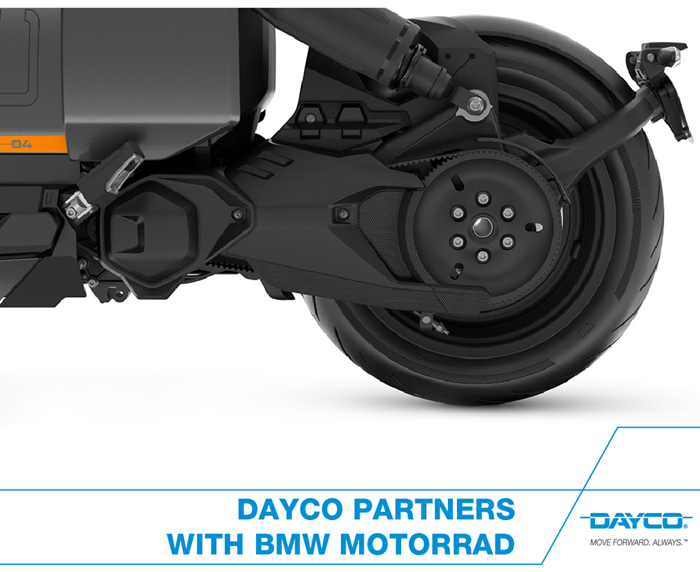

The company’s recent partnership with BMW Motorrad is one such example wherein Dayco developed and delivered a tailored final drive belt solution for the BMW CE 04 electrically powered, zero-emissions scooter, with an ambition to bring a substantial impact on the personal and urban mobility segment.

Dayco’s robust and efficient high-quality timing belt for rear-drive application delivers high system performance with an increased driving range, which allows the BMW CE 04 to run smoothly and silently. This optimized complete belt drive solution was designed and developed with close engineering support and a strong partnership with BMW Motorrad.

“Dayco has the most silent, maintenance-free belts, which can be customized as per the customer requirements and have best-in-class NVH performance, with no lubrication required. Our timing belt drive supplied for the BMW CE 04 is clean and lightweight and in contrast to the conventional chain, doesn’t stretch, which makes it the safest solution for all the personal mobility drivetrain applications,” stated Wouter Nijenhuis, Executive Vice President of OE Sales and Business Development, Dayco.

For more than 115 years, Dayco has delivered innovative energy-saving timing belt drive solutions with reduced power losses for the next generation of scooters, bikes, e-bikes, and motorcycles. Dayco also continues to embrace new technologies and smart partnerships to achieve a sustainable environment. This collaboration between Dayco and BMW Motorrad is a steppingstone on the path to reducing CO2 emissions with chain to belt conversion, focusing on the urban mobility segment.