Shift presents both opportunities and challenges for auto component players

Revenue of the electric vehicle (EV) components’ market in India is likely to rev up at a compound annual growth rate of ~76% to Rs 72,500 crore in fiscal 2027 from Rs 4,300 crore last fiscal.

That will take the share of EVs in the overall automotive components market to 9-11% — up from a negligible 1% currently — even as the supply of parts for internal combustion engine (ICE)-driven vehicles also rises.

Says Pushan Sharma, Director, CRISIL Research, “Improving cost viability of EVs versus ICE vehicles, and rising consumer demand for environmentally cleaner mobility will drive the transition to EVs. Among the key auto segments, two-wheelers and passenger vehicles (PVs) are seen driving the transition, with their penetration rising to 19% (from ~2.5% currently) and 7% (from less than 1% currently), respectively, over the next five fiscals[1]. Commercial vehicles, the other large auto segment, will see far lower penetration at ~3% (0.3% currently) because of unfavourable economics.”

The transition to EVs will create both opportunities and challenges for domestic auto component makers, indicates a CRISIL analysis of 220 manufacturers, which account for a-third of the auto components market.

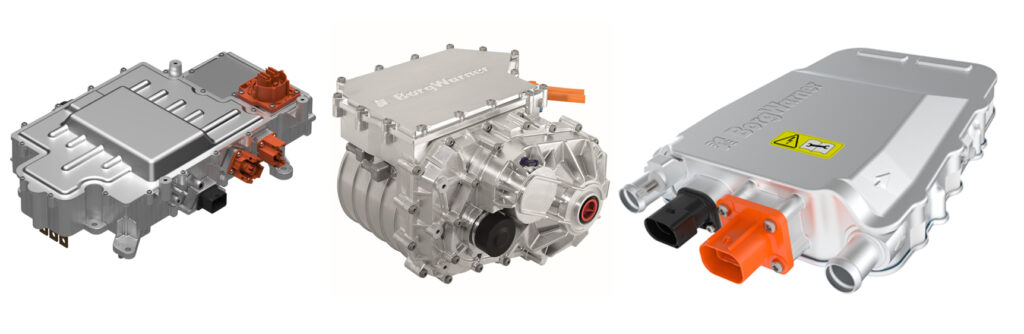

Says Naveen Vaidyanathan, Director, CRISIL Ratings, “EV components such as batteries (60% of EV component revenue by fiscal 2027), drivetrains (15%), electronics (15%) and others (10%) present an opportunity for auto component makers to diversify their revenue base beyond ICE vehicles. Companies are already investing in developing electric components, both with established ICE original equipment manufacturers (OEMs) and with new-age, pureplay EV makers. Almost 90% of the EV component supplies will be for two-wheelers and PVs.”

For makers of traditional auto components, about 75% revenue comes from body parts, chassis, suspension, electrical, braking, lighting, and seating. These are parts of EVs, too, so growth is unlikely to be a challenge for such components. While companies may need to partially re-engineer products for EVs, they will be able to do so with incremental investments.

It is the balance ~25% of auto component supplies catering specifically to ICE engines and transmission components that could face challenges due to the EV transition. These include parts such as starters, alternators, fuel injectors, radiators, gear box, clutch, pistons, cylindrical block and exhaust system critical in an ICE vehicle but redundant in EVs.

But here, too, with the transition set to be faster in two-wheelers, auto component makers with concentrated exposure to this segment will be more at risk compared with others supplying to PVs or CVs. To illustrate, engine and transmission component makers supplying majorly to two-wheelers account for only about 6% of the revenue of auto component companies rated by CRISL Ratings.

Pertinently, majority of the auto component makers (~50%) cater to multiple end-segments. Companies are also looking to de-risk their models by supplying EV components and increasing non-auto and industrial products in their portfolio.

All said, given the pace of transition to EVs, individual companies could gain or lose disproportionately depending on their product portfolio, customer mix, ability to reengineer, and balance sheet strength. These would be monitorables in the road ahead.