The device provides the necessary measurement data to the battery management systems (BMS) and ensures a balanced state of charge through cell balancing.

Infineon Technologies AG is expanding its product offering for battery management systems with a new sensing and balancing IC – the TLE9012AQU. The device is specially designed for batteries in hybrid and electric cars, but also suitable for other applications. It measures the voltage in up to twelve battery cells with an accuracy of ± 5.8 mV over the entire temperature and voltage range as well as the operating life cycle. Furthermore, it supports up to five external temperature sensors, provides an integrated cell balancing function and uses an iso-UART interface for communication.

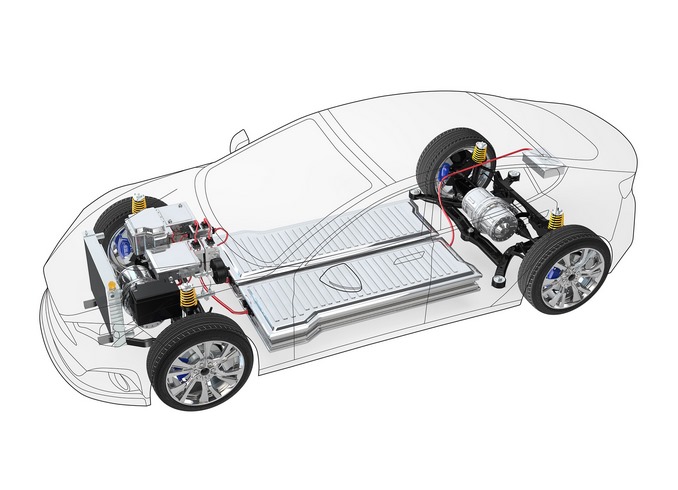

Battery management systems (BMS) ensures that the capacity of a battery is optimally utilized, i.e. that the longest possible range is achieved in an electric car, and that the battery does not age prematurely. In addition, they determine the battery’s state of charge and state of health in order to estimate the available range and remaining service life. The new IC provides the necessary measurement data and ensures a balanced state of charge through cell balancing. Among other things, this prevents the weakest cell from determining the total usable capacity of the battery.

To minimize the influence of interfering signals on the measurement results, the new sensing and balancing IC from Infineon features a programmable noise filter. In addition, it performs the measurement in all cells simultaneously so that the results remain comparable even in the presence of temporary interference factors. A compensation algorithm with integrated stress sensor and extended temperature compensation ensures the long-term stability of the measurements.

Cell balancing is achieved via twelve balancing switches integrated on the chip – one per channel. They are designed for currents up to 150 mA. For higher balancing currents, the device also supports external switches. In addition, the cell balancing can be programmed to stop without a signal from the microcontroller after a defined time of up to 32 hours or when the cell has reached a defined voltage. This allows the microcontroller to switch to sleep mode and thus save energy.

With its twelve channels, the TLE9012AQU is particularly suitable for batteries that are partitioned with twelve cells per module. One device is then required per module. The iso-UART interface for data exchange between these modules and with the micro-controller allows easy voltage isolation and ensures data integrity. The communication supports more than 20 serially connected devices and a ring topology. This ensures that even if a single device fails, the communication chain is not broken and the rest of the system remains functional.

The German company is also launching TLE9015QU battery monitoring transceiver IC designed for connecting several TLE9012AQU devices in a daisy chain inside a Li-Ion battery. By means of its two UART and iso UART interface pairs it can support ring communication improving the availability of the system by a low cost. Both the devices will be available in July 2020.