India’s leading automotive components major – the Kinetic Group today announced readiness of its advanced battery manufacturing facility at Ahmednagar. With an investment of Rs. 50 crore, the facility marks the Group’s entry into EV battery manufacturing that will make Range-X brand of batteries for two and three-wheeler electric vehicles (EVs).

Located in Ahmednagar, the facility comprises high-tech manufacturing unit that have a production capacity of 60,000 high-performance battery packs per year. The facility will also be manufacturing both LFP and NMC type of batteries. Customisable for Two- and Three-wheeler EVs, the company plans to supply the batteries to OEMs beyond the Kinetic Group. The electric vehicle (EV) market in India is expected to grow at a CAGR of 28.52%, reaching US$ 18.319 billion by 2029, which will benefit the facility, as it is set to supply batteries for two-wheelers. Additionally, the facility is developing prismatic cells for three-wheelers.

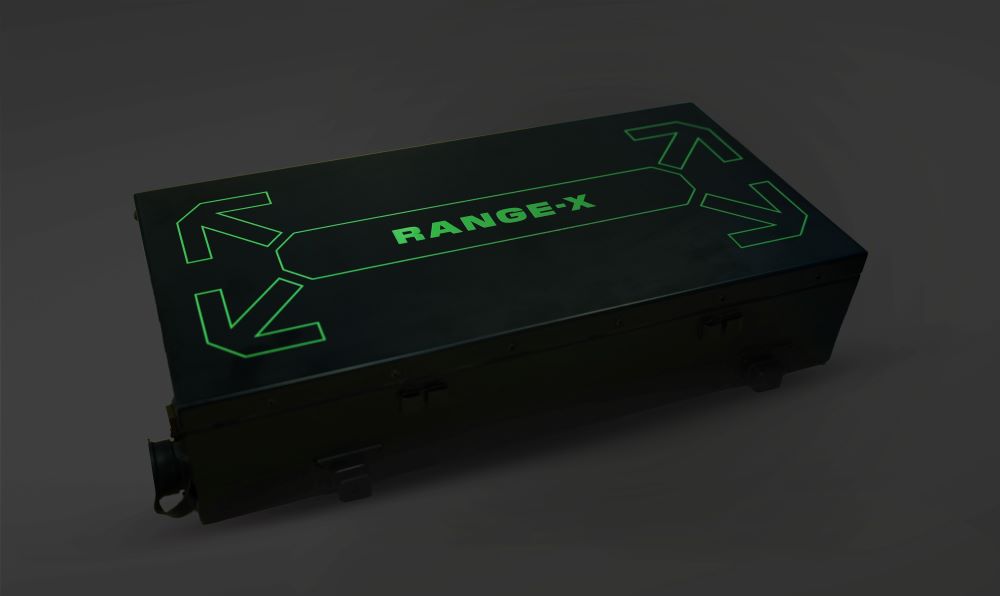

Kinetic Group’s Range-X batteries are powered by the latest Lithium Ion Phosphate (LFP) technology. The batteries are equipped with stable chemical composition which significantly reduces the risk of thermal runaway, delivering peak performance in extreme temperatures and smart BMS Integration that enhances efficiency and overall battery health. The Eco-Conscious Design manufactured using non-toxic, recyclable, and ethically sourced materials, makes for an environmentally responsible choice.

The company is also set to manufacture Nickel Manganese Cobalt (NMC) batteries built on exceptional energy density technology providing longer lasting power for a wide range of applications. The NMC batteries will deliver superior performance with a high charge-discharge rate, ensuring reliable operation even under demanding conditions.

Ajinkya Firodia, Vice Chairman and Managing Director, Kinetic Group, said, “Range-X is a result of pioneering work in batteries and a significant step towards India’s mobility transformation. The Ahmednagar facility represents our dedication to self-reliance, safety and sustainability in battery technology. By integrating cutting-edge automation and smart technology, the facility ensures reliable, efficient and clean energy solutions.”

The facility’s core constitutes a automated production line integrated with IoT-enabled POKE-YOKE systems and stage-wise inspections. These systems ensure precision, quality, and safety at every stage of manufacturing, in compliance with industry standards including AIS 156, & AIS 004. In addition to this, Kinetic Group is working on advanced technology and localisation of the BMS, PLI Schemes phased by the PM E-drive for Make in India initiative. This alignment underscores Kinetic Group’s commitment to maintaining world-class safety and performance standards, whilst adding to the company’s achievements in EV and component manufacturing.