With its next generation of pure electric cars, Volvo Cars aims to offer customers a longer range, quicker charging and lower costs, and reach new milestones in automotive safety and sustainability.

To realise these ambitions, Volvo Cars will invest SEK 10 billion in its Torslanda manufacturing plant in Sweden in coming years, in preparation for the production of that next generation of fully electric cars.

As part of the planned investments, the company will introduce a number of new and more sustainable technologies and manufacturing processes in the plant. These include the introduction of mega casting of aluminium body parts, a new battery assembly plant and fully refurbished paint and final assembly shops.

The investments follow on a recent announcement by Volvo Cars and Northvolt, the leading battery cell company, to invest SEK 30 billion in the development and manufacturing of high-quality, tailor-made batteries for the next generation of pure electric Volvo models.

Both investment plans represent new steps towards Volvo Cars’ ambition to be a fully electric car company by 2030 and reflect the company’s commitment to a long-term future in its hometown of Gothenburg.

“With these investments we take an important step towards our all-electric future and prepare for even more advanced and better electric Volvos,” said Håkan Samuelsson, chief executive. “Torslanda is our largest plant and will play a crucial role in our ongoing transformation as we move towards becoming a pure electric car maker by 2030.”

The introduction of mega casting of aluminium body parts for the next generation of electric Volvo models is the most significant and exciting change implemented as part of the investment package. Mega casting creates a number of benefits in terms of sustainability, cost and car performance during the cars life time, and Volvo Cars is one of the first car makers to invest in this process.

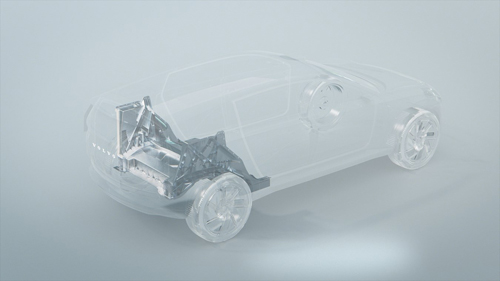

Casting major parts of the floor structure of the car as one single aluminium part reduces weight, which in turn improves the energy efficiency and thereby the electric range of the car. This also allows Volvo designers to optimally use the available space inside the cabin and luggage area, boosting the overall versatility of the car.

Other benefits from mega-casting include reduced complexity in the manufacturing process. That in turn creates cost-savings in terms of material use and logistics, reducing the overall environmental footprint across the manufacturing and supply chain networks.

The upgrade of the paint shop involves the installation of new machinery and implementing new processes, which are expected to support the ongoing reduction of paint shop energy consumption and emissions.

A new battery assembly plant will integrate battery cells and modules in the floor structure of the car, while the assembly shop is being refurbished for the accommodation of next generation fully electric cars, for example with a new ‘marriage point’ where the top body and the floor of the car meet for the first time.

The logistics areas will also be refurbished, improving material flow and optimising the transport of goods and parts into the plant. The company will also invest in facilities around the plant, such as break areas, locker rooms and offices that further improve the working environment for all employees.

“Today is a great day for the Torslanda plant as we are making it fit for the future with this investment package,” said Javier Varela, head of engineering and operations at Volvo Cars. “Our future as a company is all-electric and that requires a variety of upgrades across the plant, to ensure that Torslanda can continue to build premium electric cars of the highest quality.”

The Torslanda plant has an annual production capacity of 300,000 cars and is one of Volvo Cars’ longest-operating manufacturing facilities. It was opened in April 1964 by Swedish King Gustaf VI Adolf and was for a long time the largest single workplace in the country. Currently, the Torslanda plant operates on three shifts and employs around 6,500 people.