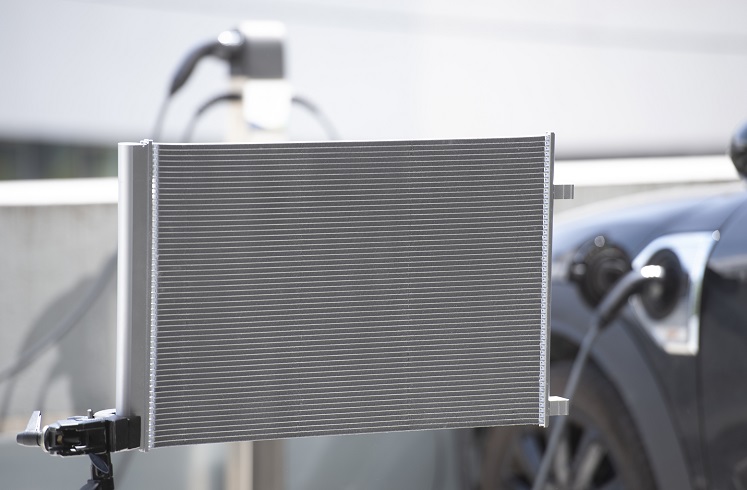

As part of the battery cooling system, the new condenser offers significantly higher power density that provides for optimum cooling of battery and cabin without the need for extra installation space, while also protecting the battery against excessive temperatures during fast charging.

MAHLE has introduced a new type of condenser for hybrid and electric vehicles that helps to accelerate traction battery charging. This new design offers significantly higher power density than the current one. As part of the cooling system, the condenser is one of the components that ensures the battery is optimally cooled during fast charging and reliably protected against damage. The new condenser also provides sufficient cooling capacity for comfortable temperature in the cabin without taking up additional installation space. Because fast charging is a key factor in the acceptance of electric vehicles, the latest innovation contributes toward making this form of transport more suitable for everyday use and the mass market, claims the company.

Until a few years ago, the most critical task of the engine cooling system was to protect the combustion engine from overheating under high loads. The thermal management of electrified vehicles has become much more complex including stronger interactions between cabin and powertrain thermal management and the need to maintain components such as the battery within tightly defined temperature limits. MAHLE has responded with a large number of innovations for the thermal management of electrically powered vehicles, thus enabling the success of new forms of mobility.

Thermal management components from MAHLE can be found in hybrid, battery electric, and fuel cell powered vehicles. Striking a balance between performance, installation space requirements, comfort, and systems costs is key. MAHLE meets these challenges by taking a holistic approach in the design of the entire thermal system and optimizing the interactions of each component. MAHLE is thus able to increase battery life and cruising range as well as passenger comfort and the performance of the drive system, thereby significantly contributing to the increased acceptance of alternative drives.

“Battery cooling is crucial for the performance of electric vehicles. In developing our new condenser, we were able to draw on our many years of expertise in thermal management,” explains Laurent Art, Director Advanced Engineering Thermal Management at MAHLE. “We’re confident that this condenser will give a further boost to the development of electric vehicles.” Alongside the component design, the production process is also optimized to provide a lighter product that is less susceptible to corrosion and requires less refrigerant.