Committed to sustainable mobility solutions revolutionising the trucking industry, US-based ElectronEV has announced its foray into India to roll out light, medium and heavy commercial EVs. With a substantial fleet of commercial EVs running in the US, the brand is finally introducing its unique services, including customised EVs, vehicle management solutions, fleet management solutions, digital cockpit and IOT solutions, real-time data analytic solutions and charging infrastructure to the fast-growing Indian market. In this exclusive interview, Rajesh Rajgor learns more from Rakesh Koneru, Founder, ElectronEV, on how it plans to address issues with battery technology limitations, high capital costs, the cost of electric vehicles, availability of charging infrastructure and the amount of time it takes to fully charge an electric vehicle.

Could you elaborate about the genesis and technology behind ElectronEV?

ElectronEV is a vertically integrated, end-to-end mobility start-up that manufactures zero-emission vehicles (OEM) and eco-systems for the light, medium and heavy-duty commercial vehicle industry in the global markets. With global aspirations, ElectronEV has cross-border teams based out of California, USA focused on new product innovation and Telangana, India focused on application-driven engineering and manufacturing for Indian needs. Cross-border teams help ElectronEV to bring the best of both worlds.

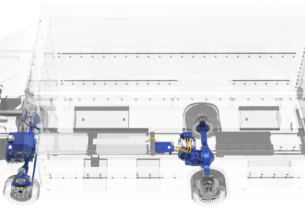

In line with the long-term vision of the company to create customer-centric end-to-end mobility solution, our IP creation and product innovation started three years back with electric powertrain system platform called ‘Amber’. This is our proprietary technology stack which includes battery pack and battery management system, traction inverter, motor and charging systems, digital driver interface and connectivity, chassis power management and digital control. With Amber, we will be providing energy-power dense, highly efficient, and robust powertrains which will be most economical to scale, own and use on any chassis platform. Our autonomy over the software stack will assist in delivering customer-centric products, solutions and services at the end of the manufacturing line.

The Amber platform is created, designed and innovated by founding team and industry experts from Silicon Valley for the global market. It is ElectronEV’s first generation platforms built, tested and benchmarked to automotive and aerospace standards with respect to thermal, NVH, EMC and high-voltage safety. The software and hardware design and development follow the ISO26262 methodology. The company internally is very stern in adopting and practicing best processes from the automotive industry like DFMEA, 8D problem solving and Six Sigma in both engineering and operations.

Indian consumers are price-sensitive. Automobile prices for both passenger and commercial vehicles are at an all-time high. How do you package ElectronEV products to make them affordable and at the time scalable for the Indian fleet operators?

Being an end-to-end technology mobility company enables ElectronEV to provide purpose-built vehicles tailor-built for fleets’ economical requirements. Our smart and application-driven vehicles will help in reducing the overall packaging cost of vehicles. ElectronEV’s IP stack will enable vertical integration for better control component costs and supplier dependency. The localised supply chain helps in reducing capital expansion towards vehicle build, shipping costs and enables just-in-time production effectively. Reduction of factory overheads is made possible through micro factories. Well-to-wheel further expands into ElectroEV providing flexible and unique ownership models with a goal to speed up mass adoption of zero-emission commercial vehicles. Our flexible ownership models are tailor-made to fit all uses and economical cases, right from outright purchase, lease-based, subscription-based, battery subscription and truck as a service.

Could you elaborate on the testing, validation and certification of the technology used in products that make them stand out in their offerings?

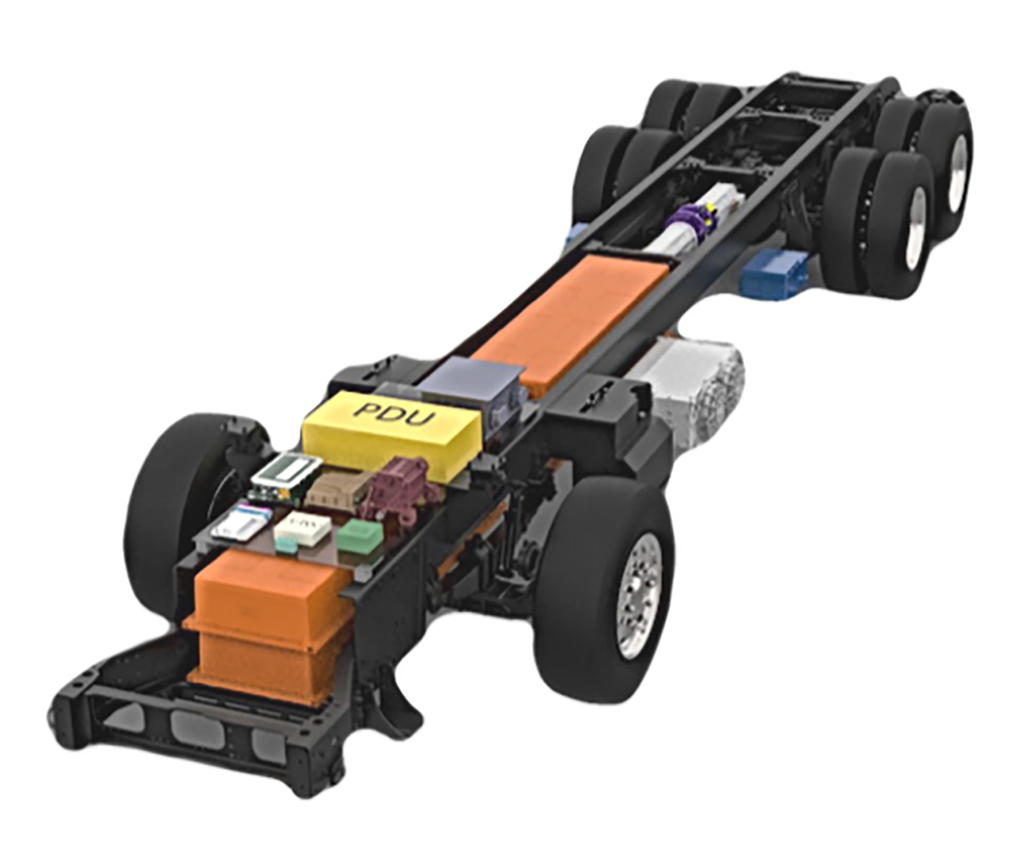

In India, we are currently working with ARAI to have Amber certified as a repower conversion platform for 7, 8, 10, 12 and 15-ton GVW. We will be deploying Amber aggressively across various vehicle platforms for customers in India in the next two years. Additionally, we will also be participating in the country’s charging infrastructure and ecosystem to deploy our own Level 2 AC charging stations strategically to assist our customers with end-to-end mobility services. These stations will be UL-rated and are designed as per IEC standards and very shortly certified to BIS standards IS 17017. Our next goal in about 12-18 months’ timeframe is to have our own intelligent and smart chassis platform called ‘Intelligent Adaptive Chassis’ (IAC) which will be the first lightweight composite skateboard structure indigenously designed to house up to 300 KWh energy and produce 350 KW of maximum power.

We will also be the first to adopt a unique manufacturing methodology where 90% of the material can be recycled and manufacturing process will be very sensitive to material wastage. IAC will enable different vehicle bodies to be integrated for end-customer usage such as box truck, flatbed truck, vans, trailer trucks, buses, specialty vehicles, etc. This will allow us to increase our customer base from end-users, transporters to OEMs themselves. Our long-term goal is to understand EV adoption on a large scale where we design, build, own and operate vehicles for a specific route where vehicle is provided as service along with an energy-efficient charging ecosystem – truck as a service, energy as a service aka the ‘Uber of Trucks’.

Where do you manufacture your products and what’s the monthly capacity? Are they fully made in India?

At ElectronEV, we are focused on a phased approach towards manufacturing. Our immediate goal as a first step for ElectronEV in the next 12-18 months is focused on localising the supply chain and contract manufacturing to handle a minimum of 100 vehicles per year. Our intermediate goal is also focused on bringing in-house assembly capabilities coupled with contract manufacturing to handle a minimum production capability of 300 vehicles per year within the next 24 months. Completely localised and vertically integrated vehicles on flexible production lines is ElectronEV’s long-term strategy. Our approach towards volume factory through micro factories is unique and is focused towards promoting localisation and creating a circular economy. Each micro factory is set to handle 15,000 vehicles per factory per year.

How many direct distributors or dealers do you currently have across India and what’s the order pipeline currently to handle the demand?

Unlike conventional vehicles, zero-emission vehicle technology is still in nascency stages and ElectronEV strongly believes that educating the local communities is extremely important to enable for wider adoption of these vehicle platforms in the near future. With the above in mind and as a driving force, ElectronEV will adapt a dual approach towards sales:

Direct Sales: Unlike other traditional vehicle manufacturers who sell through franchised dealerships, ElectronEV also plans to sell directly to consumers. It creates a better learning and buying experience. By direct involvement in the sales channel, ElectronEV believes it can gain an advantage in the speed of its product development.

Partnerships: Along with direct sales model, ElectronEV will also work towards a localised and distributed sales or service network. Partnerships will be uniquely positioned focused on infrastructure, expertise, sales and service coverage to support the rapid growth of zero-emission commercial vehicles for all classes of trucks in an area of the country that is experiencing rapid testing and adoption of this technology. We are presently in discussions with one of the major dealer networks for the same.

Who are your major clients in India and how do you cater to their varied requirements?

Our major clients with whom we are currently engaged with are logistics players in the space of e-commerce, food and grocery retail industry that would need refrigeration and freight companies in the last and middle mile delivery segment. In the off-road segment, we are working with ports to develop a custom product in the higher tonnage space of 25-60 tons.

Could you share details of any recent orders, awards and recognition that testify your efficiency, growth and success?

An LOI with first potential customer is in place for a pilot project of 100 trucks with 5,000 vehicle opportunities post pilot. Several other MOUs are in place with the potential to add at least 500 more vehicles in the near future and more in works. We won two awards at the Telangana EV State Summit 2022, namely, State Champions: Smart Innovation Award and State Champions: New State Initiative Award. ElectronEV received its first potential order from India’s one of the largest e-commerce companies. Also, ElectronEV is in discussion with companies for securing orders across a wide range of usage, tonnage and vehicle application markets. Some include ports, food and milk packaging, heavy equipment manufacturers and operators in the energy sector.

What about ElectronEV’s talent strength in engineering, software and hardware development and how is it on par with the developed markets of the world?

ElectronEV has two locations – Bay Area California, USA and Hyderabad, India. With US and India being the initial go-to markets, the US entity will design and build advanced zero emission systems utilising the Silicon Valley ecosystem while the India entity will be focused on application-specific vehicle integration, manufacturing and end-to-end mobility service. The team in US comprises industry experts in the field of commercial vehicles both from design and manufacturing end. As we are a vertically integrated powertrain company, our engineers come from aviation, industrial and automotive backgrounds in the areas of transportation design, chassis and battery systems, electric motors, power electronics, material sciences, physics, embedded systems and software.

Being in California helps significantly to stay ahead of the game as we can work with the most creative minds with tremendous industry experience. Our team in India is led by Chinna Polukanti, an IIT graduate with more than a decade experience working with various OEMs in the electrification space. His team comprises mainly of experts, engineers and consultants who focus on integration of powertrain systems to the vehicle chassis and close the loop with the end-customer. Additionally, we are actively hiring talent in India towards production and operations of the micro factory. The combination of technology from both US and India in the long run will foster reliable and efficient vehicles being manufactured and delivered to end-customers.