The innovative heat management system scavenges waste heat to warm the cabin without significantly impacting driving range in low temperatures.

Hyundai Motor Company and Kia Motors Corporation have revealed new details of their innovative heat pump system, deployed in the South Korean brands’ global electric vehicle (EV) line-up to maximize their all-electric driving range in low temperatures. It enables EV users to heat their car’s cabin in cold weather without significantly impacting electric driving range, unlike other EVs.

The new system scavenges waste heat from an increased number of sources for optimum cold-weather EV range. These innovations mean that electric cars offer more consistent range in temperatures where other EVs start to see a significant decline in the distance possible from a single charge. Equipped with the latest heat pump technology, the Kona Electric proved this in a recent test in Norway, the most advanced EV market in the world.

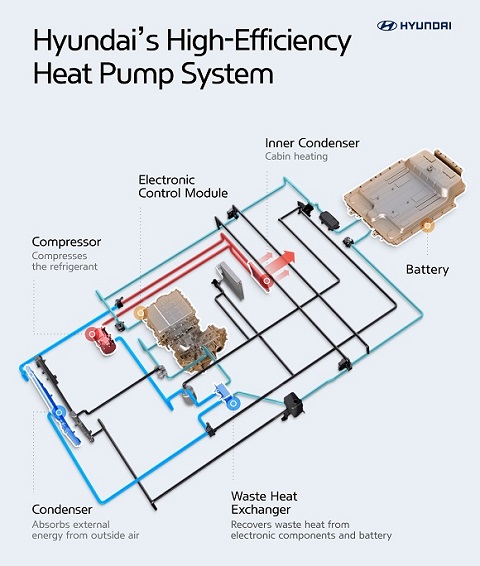

The technology was first introduced in 2014 on the first-generation Kia Soul EV. Comprising a compressor, evaporator and condenser, the heat pump captured waste heat given off by the vehicle’s electrical components, recycling this energy to heat the cabin more efficiently. The system has now been developed further for new EVs line-up of Hyundai and Kia brands.

Hyundai claims that the heat pump now harvests significantly more energy by recycling additional waste heat not only from power electrics (PE) modules (such as drive motors, on-board chargers, and inverters), but also from the battery pack and slow charger. The system uses the heat generated by these components to vaporize refrigerant from liquid to gas form. High-pressure gas is discharged from the compressor and forced into a condenser to be converted back into a liquid. This process generates additional heat energy that is recovered by the heat pump and used to warm the cabin.

This captured energy improves the efficiency of the HVAC (heating, ventilation and air conditioning) system, recycling it to more efficiently heat up the cabin and minimize battery power consumption. By reducing the load on the battery, the heat pump cuts energy consumption from the HVAC system, maximizing the available electric driving range of the car.

This innovation means the latest e-cars from Hyundai and Kia offer around twice as much driving range and battery capacity compared to the their first-generation models – and are capable of travelling significantly further on a single charge. For example, the first-generation Soul EV offered owners an electric driving range of around 180 km from a single charge of its 30 kWh lithium-ion polymer battery pack. The second-generation Soul EV, with a 64 kWh battery occupying a similar amount of space, is capable of traveling up to 386 km on a single charge.

The companies are also realising major improvements in heat management for the EV battery packs. A water-cooling system for Hyundai and Kia’s EV battery packs, rather than conventional air cooling, have yielded further increases in range without increasing physical dimensions. This development means battery cells in the EVs can be packaged much more tightly, with water-cooling channels taking up less space than air-cooling channels, increasing battery density by up to 35 percent.