With electric and hybrid vehicles becoming more mainstream and autonomous vehicles awaiting a grand roll-out, the automotive industry has been under considerable pressure from governments and society to pursue a more sustainable model of growth. Klüber Lubrication India understands that this transition also brings with it demanding expectations from consumers on ride comfort and safety standards. So, in cooperation with various partners from science and industry, we have developed innovative speciality lubricants to bring new solutions to the market that would make electric mobility highly efficient.

Lubrication challenges in EVs

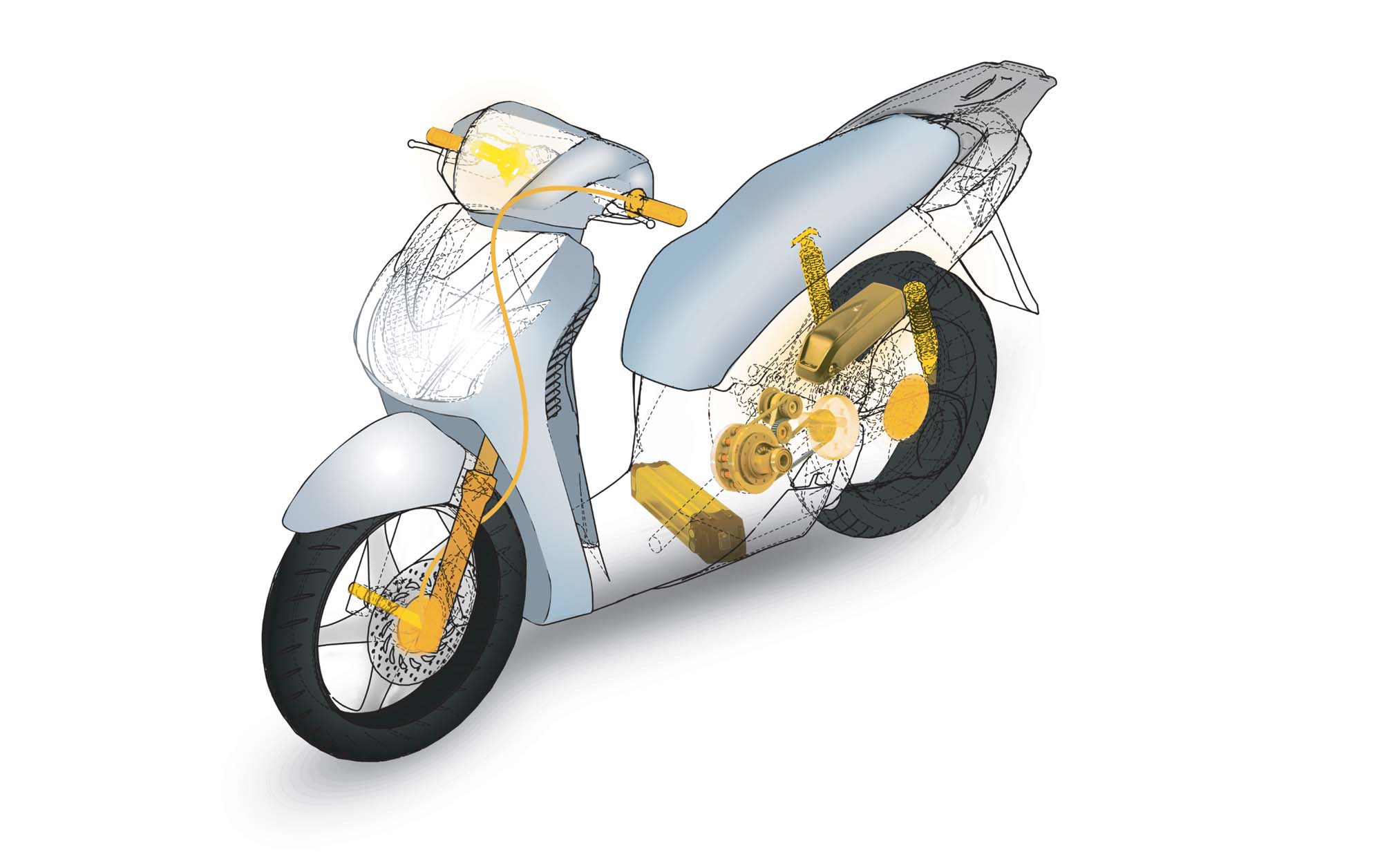

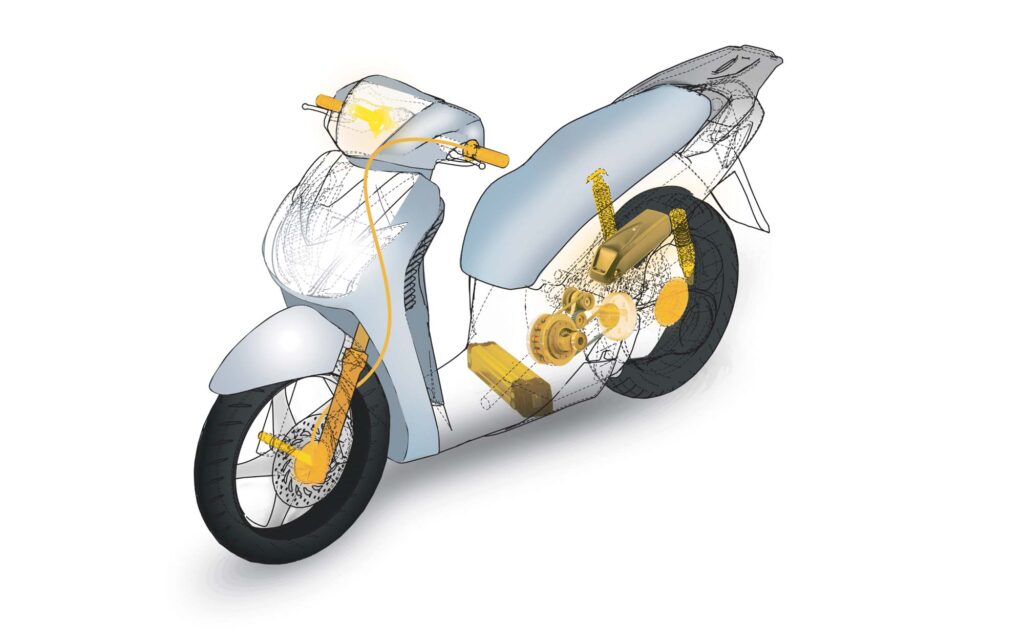

As the automotive industry moves towards electric vehicles to address the need for cleaner mobility, it faces a new set of lubrication requirements different from traditional ICE vehicles. OEM developing parts and assemblies for EVs in the two-wheeler/three-wheeler and passenger vehicles segment are extremely particular on the need to curb unwanted noise, vibration, electric erosion, and other similar challenges. This host of issues cannot be tackled using traditional lubricants.

New mobility solutions on the fast track

Klüber speciality lubricants are made with high-quality raw materials and special additives that are dynamically light with low friction properties making them the most suitable option for the industry. Several components in EV’s are made from plastics like POM / PAM / PA6 or Delrin, to reduce weight. Klüber Lubrication ensures that our EV lubricants are compatible with the aforementioned polymers.

Although a lot of standard applications remain the same in ICE and EV vehicles, quite a few moving parts have become redundant in EVs. These include the powertrain, propeller shaft, starter motor, and water pump among others, thus making noise and vibration control one of the most challenging issues faced by EV OEMs. On a similar note, the brake judder and squeal, suspension, and steering ride comfort too require high-performance lubricants in order to avoid the aforementioned issues. Klüber speciality lubricants are specifically designed to overcome such NVH issues, having proven industry experience to meet these stringent requirements.

Also, with the development of EVs, we have seen a few unconventional applications like charging gun actuators, throttle positioning sensors, and combi brake systems among others, where traditional lubricants are not able to fulfill OEM requirements. Klüber India is currently working with OEMs as well as their Tier 1 suppliers to understand these requirements and suggest suitable lubricants from our exhaustive portfolio of products and initiate new developments if needed.

A few of the application references and their consequent development processes are outlined below:

Charging gun actuator (Solenoid actuator): The current OEM requirement is to develop a charging gun with a toggle mechanism that helps to lock it in the vehicle for faster and more efficient charging. Over a sustained usage period this toggle mechanism undergoes wear, making it loose which results in slow charging. In order to overcome this issue, Klüber India has developed a suitable lubricant that eliminates wear. Application of a miniscule amount of this speciality grease prevents the dreaded slow charging issue.

Throttle Positioning Sensor: In ICEs the speed and throttle are controlled by wire through a butterfly valve. In EVs, the speed of a vehicle is controlled by controlling current / voltage fed to the motor which in turn is controlled by a suitable variable frequency drive that is fitted in a 2W handle. To meet this demanding requirement Klüber India has developed an efficient di-electric grease that prevents excess electrical discharge and is entirely compatible with plastics.

Combi Brake System: An electric vehicle’s requirement of a braking system is quite different from the conventional design as an EV requires a suitable brake with minimal judder and squeal. Moreover, it should be able to deliver optimal braking efficiency without any skid or heating of components and should also provide regenerative braking. To target and overcome this challenge, Klüber India has developed a suitable moly-based grease that provides optimum performance and avoids any wear in braking sub-assembly components.

High-performance lubricant for electric drive train: EV powertrain requires high-performance, efficiency, and low power consumption to improve the overall mileage (km/charge). To this end, Klüber Lubrication has developed a fully synthetic high-performance gear oil based on polyalphaolefin (PAO), which offers high shear stability and protection. The excellent shear stability of the synthetic base oil ensures sufficient lubricating film thickness even under high loads. Due to the excellent aging and oxidation stability of the synthetic base oil, oil change intervals are much longer than with mineral oils, thus reducing maintenance costs. Similarly, for electrical traction motors, Klüber has suitable greases that reduce electrical erosion and ionic discharges.

Why Klüber?

Klüber Lubrication has an extensive portfolio of efficient solutions for challenging requirements. The existing lubricants are under constant development, particularly with regard to temperature, long-term stability, higher loads, and ever-increasing efficiency requirements. When developing custom solutions, Klüber Lubrication benefits from decades of proven and practical experiences in the automotive field.