Since early this year, the first electric articulated bus equipped with a Konvekta CO2 heat pump thermal management system has been operated by the public transport company VAG in Nuremberg.

The e-bus is the emission-free alternative to diesel buses. If one wants to do completely without fossil fuel, the AC components must also be accommodated in battery power. Electric buses don’t produce exhaust heat which could be used to heat the passenger compartment. In solo buses the efficient temperature control has already been managed quite well. But temperature control in articulated and double-deck buses is a new challenge.

Due to its length of more than 18 meters, the electric articulated bus needs more than one thermal management system which have to be networked optimally. Furthermore, the demands on air conditioning systems have changed. Classical applications comprise the air conditioning of the bus interior (driver’s place and passenger compartment). Today’s demands have been increasing. Thus, for example the temperature control of the batteries has to be integrated in the thermal management system because batteries need an optimal operation temperature frame to reach the maximum range and lifetime.

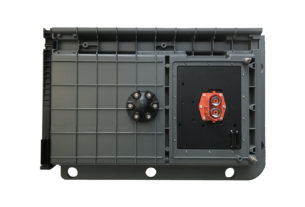

The first Konvekta CO2 heat pump for e-articulated buses

Since the beginning of this year, the first-ever e-articulated bus equipped with a Konvekta CO2 heat pump has been in scheduled service on routes in Germany. The central part of the Konvekta CO2 heat pump management system are the two UltraLight 500 CO2 heat pumps 2.0 on the front and rear section, including the 2 energy carrier modules for hot and cold water. Both systems run on the refrigerant CO2.

The heat pump system is the most intelligent and effective heating technology in the field of electromobility because a great part of the provided heating energy is sourced from the ambient air and not from fuel or electricity. To obtain 100 per cent heat, it needs at best only 25 per cent operating power (current) from the battery. The rest of the needed energy is gained free of charge via the thermodynamic cycle from the ambient. Depending on the vehicle type, the CO2 heat pump consumes for example at -10°C approximately 45 kWh electric energy per 100 km in contrast to conventional electric heating components that consume more than 100 kWh for the same distance.

It saves the operator money and the environment CO2 emissions. There are significant financial advantages by using the CO2 heat pump system compared to conventional heating and cooling of e-articulated buses. The public transport company of Munich for example saves 53 per cent of the annual costs of temperature control in the e-articulated buses that are equipped with a Konvekta CO2 heat pump. That means, a CO2 heat pump system saves 1.700 € of the annual energy costs compared to an air conditioning unit with electrical auxiliary heaters.

Additionally, up to 5.500 kg of the annual CO2 emissions are avoided. It is worth considering the lower energy consumption in the procurement of new e-buses. Depending on the area of application battery capacity worth 66.000 € can be saved and the vehicle range extended up to 30 per cent. A CO2 heat pump system is the only option to temper an e-bus with regard to range optimization and sustainability.