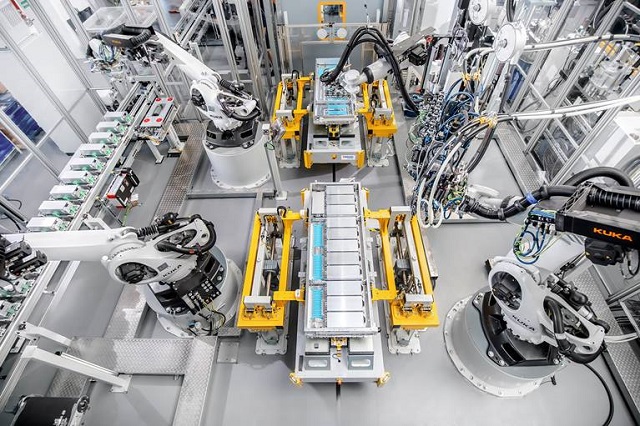

The German automation specialist has supplied the production system to Webasto that has begun production of battery packs for a European bus manufacturer.

The progress of electromobility is not just changing the landscape of automotive vehicle propulsion and energy technologies, but also making tremendous impacts on production processes. As conventional production lines for automobiles cannot be transferred to the manufacture of electrified powertrains, EV manufacturers are looking for innovative and automated solutions to make their manufacturing processes and production assemblies easy and simple.

One of world’s leading provider of factory automation solutions in the automotive industry, KUKA has recently supplied the production systems for the manufacturing of battery systems at the Webasto plant in Schierling in the Regensburg county, Bavaria. The system is designed as a multi-product line and enables the production of different battery types. A finished battery pack is produced approximately every 15 minutes.

Dr. Joachim Döhner, Battery Senior Director Global Sales at KUKA, observes:

“As an automation specialist in the automotive industry, we are already working on standardized manufacturing and assembly solutions for efficient battery pack and battery module production. KUKA also supplies production and assembly lines for fuel cells or their components.”

Assembly and handling of battery packs that consists of individual components and electronic parts require high precision in a limited space. “We have risen to the challenge and efficiently combined all the necessary process steps.”, said Dr. Döhner from KUKA. Automated guided vehicles are used to transport the required battery components to the individual production stations. The AGV also serves as a kind of central supermarket, supplying side-mounted drawers containing, for example, templates as safety instruments and positioning aids for the manual processing steps of the workers. “Our aim was to simplify the work processes in battery pack production and to safeguard them in such a way that the workers’ safety equipment can be reduced as far as possible”, he added.

Webasto started production of its standard batteries since early this year. In addition to the core business with roof and thermal systems, the automotive supplier now also produces charging solutions and battery systems for electrified vehicles of all kinds. “We are opening a new chapter with battery production”, said Dr. Hartung Wilstermann, globally responsible for the battery business at Webasto. As a long-standing partner of the automotive industry, we have been shaping trends and developments in the industry together with our customers, he added