In a comprehensive chat with Martin Liebl, Member of the Management Board, Miba AG, N. Balasubramanian gathers insights about Miba’s plans for India and how the company is placed right to serve the customers with high-performing powertrain components besides eyeing a huge opportunity in electrification of small and big vehicles.

Miba has its heart in the right place when it comes to strengthening their position in the Indian auto component market. And, Martin Liebl, Member of the Management Board, Miba AG, was on a recent visit to their new and expanded Pune facility. Responsible for Miba Friction Group, besides developing new business with a focus on decarbonization and e-mobility, Martin has a crucial role to play in the company’s strategic unit in their Automation Systems and Quality division.

Helping Machines Move Better

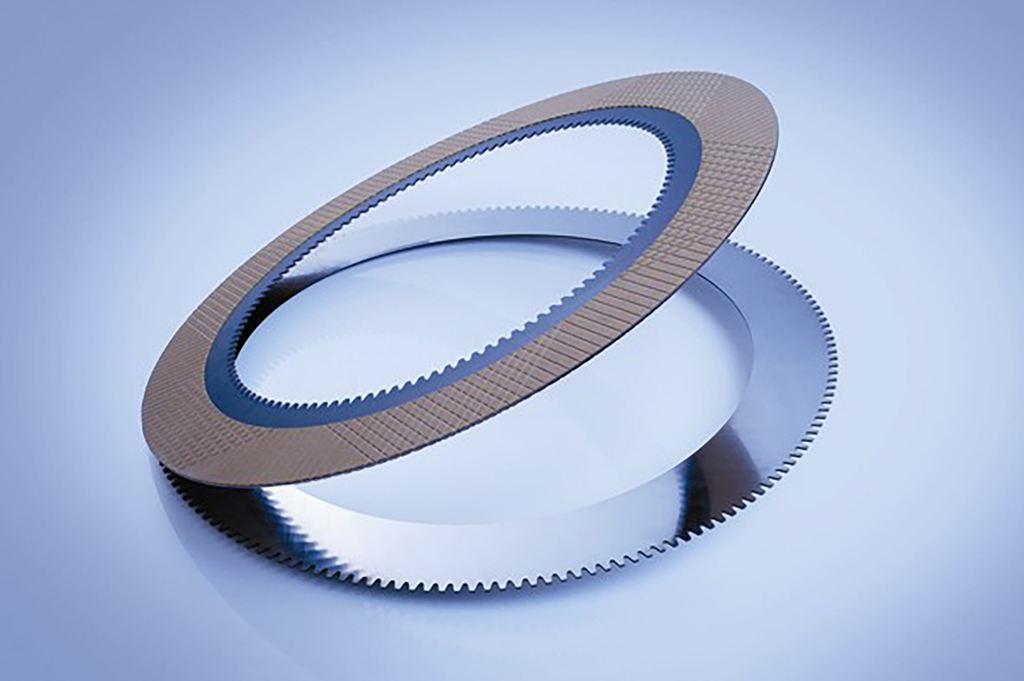

With its innovative and advanced friction technologies, Miba Drivetec India (MDI) is excited and looking forward to making huge ripples in the market with their products. Miba, the world over, is known for developing solutions for the generation, transmission, storage and use of energy.

Talking about their business in India, Martin shares: “Business is good. We are growing in the wet disc segment, bringing new business to India, garnering market share with major customers and growing with them. We are serving the off-highway, and tractor segments besides the construction industry. As the next step, we plan to localize the clutch button business for the dry clutches for tractors and trucks. Following our strategy to deliver locally for local, we have decided to localize the production and invest in the expansion of our global capacity for clutch buttons in India. Last year, we had installed capacities for clutch buttons and ramped up just in time for a big market demand due to the huge tractor production in the past year and a half.”

Miba is planning to invest in another plot of land in Pune. Overall, the investment in the equipment will be to the tune of a billion rupees and the facility will be operational around the beginning of 2023. The increased mechanization of the agriculture sector and the need for more horsepower in the tractor segment are giving Miba new spurts of growth.

Martin explains: “This means that there will be Power Take-Off (PTO) clutches which use our buttons. It may not be that the overall number of tractors will rise but the technology content of the ceramic clutches is. We believe that there will be an additional demand with the introduction of BS VI norms, which will see a shift from organic to ceramic clutches, which will also drive our demand. And we are ready for it.”

Expansion Plans

Beyond 2023, Miba is all for increasing their capacities in India. The company may even relocate operations to serve different global markets like China, from India.

He agrees: “For example, our customers prefer that we have a regional presence. Most importantly, we are highly pleased with our team here which is strong and we like to think that success is earned easier with a strong team. We are proud and happy with the way the team here has built the new production facility. With travel restrictions of people and equipment from Europe during the COVID pandemic did not deter the local team in doing a wonderful job of building by themselves, of course, our experts were guiding them online. But it is due to our India team that we have been able to ramp up quickly to our peak capacity.”

Miba’s global top management of their friction division was recently in Pune to reiterate the importance of India as a market for them.

Martin emphasizes: “India is important for us both customer wise and in terms of opportunities of growth we have here. Our entire global Friction management team visited our major customers here for a strategic level meeting and we also talked about challenges and requests for the future, localization plans of our customers’ businesses and got a better understanding of the strategy. Our plan is to expand our footprints in India much more than before, in the next few years. And in alignment with that, the next phase of expansion of our capacity is already underway.”

Advantage Miba

Miba strives for a single business goal – their components should fulfill their customers’ expectations and contribute to the final performance of the customer. Their USP lies in the fact that Miba’s clutch buttons are hardy, are built to bear superior loads and deliver superior performance because of the precision of their processes.

Martin shares: “It is true for our tractor clutches also because our buttons ensure lesser wear, and are more resistant ensuring a longer life. When it comes to premium passenger cars, our carbon discs can take heavier loads wherein the horse power gets distributed perfectly to the wheels of the axles. This is true for all-wheel drives also. Our technology is designed to give our customers an edge over competition.”

Unfailingly, Miba brings this same value to India too, while the company has a perfect understanding of the importance of cost competitiveness in India, they ensure that offering quality is what will win them the customers’ favorable opinion on a continuous basis. In Martin’s words, ‘it is the value that we deliver that sets us apart’.

India – A Competitive Market

India, for Miba, is one of the most competitive markets. The company’s aim is to help their customers bring in revenue and to ensure that they receive the best economic value – be it the OEMs or their customers.

Martin adds: “At the end of the day, our product commits to performance which is what our customers not only seek but also get. The more the horse power, the larger the equipment, the more there is the requirement for power density, resulting in more complex design to produce reliable and qualitative parts – all this, while delivering consistent performance over the years without fluctuations. And this is what Miba is capable of.”

Miba’s management sees growth opportunities in India and that is the reason behind their consistent investment in equipment, and people. As per Martin, the company is aware that the India team is performing so well because ‘they are passionate and always have a different perspective on how to do things’.

Customer’s First Choice

Miba’s strategy is to be the customer’s first choice in friction solutions, globally. Their global customers both in brakes and clutch segments, in agriculture and HCVs appreciate Miba’s reach across the world to serve them in their regions.

He explains: “We serve the same or similar products in major countries in Europe, then in the US, China, and of course, India. It is important that we cater to the same quality, and engineering service, the same product manufactured from the same processes, globally. It is important for us that our customers have two things – a) they have confidence in what we do, and b) we want to provide them convenience. We want them to feel that it is convenient to do business with Miba from wherever they want to.”

The Miba Friction Group has two plants in Europe – one in Austria, and the other in Slovakia. The company produces their own friction material in their plant in the Czech Republic, making it unique not only because not many others can boast of it but also because it enables Miba to provide the whole technology chain for their customers.

He elaborates: “We have the advantage of being cost effective, and offering stable quality. We are reliable, capable, and have highly sophisticated, high-performing, and high power-density products. We can serve our customers wherever they are.”

Technological Advantage

Miba takes its R&D seriously and hence focuses on offering innovative solutions to the technologically-demanding customer.

He agrees: “With our components, one can tweak the last performance out of say a high-performance car or even a tractor. We strive to answer expectations of a superlative performance from the OEMs to their customers. For example, if a mining truck has a 400-ton payload, and the truck itself weighs say 400 tons, its total weight is 800 tons. The energy it will require to just brake while going downhill at 50 kmph is huge. Such a truck will require high-tech components to be reliable because there can be no margin for errors. And we offer that.”

Miba is now bringing technology leadership into electrification also, which according to Martin, is even more demanding in the axles because there is more torque, and where there is 30,000 or so reps per minute making the engagement even more critical.

Martin says: “We can bring our expertise and our leadership in the axle clutches. And, already the leaders in electrification like Porsche Taycan use our discs in the differential lock to distribute the power. And it is the first real high-performance car in the market which has this feature. It shows how far ahead we are in that technology.”

Opportunities and Roadmap Ahead

As far as the Indian market and future is concerned, Miba is already armed with growth and expansion plans. The potential for e-mobility in India is poised to give a big push to Miba. Also, with the transition to BS VI norms in India, Miba has been eyeing the opportunities that come with upgrades that are needed in the product and the demand for future high-performance trucks. The company’s future plans include catering to the market when it shifts to automated transmission in passenger cars. Since the market’s choice of technology is still in the making, Miba is keeping its next move close to its heart. Yet, they will for sure cater for niche applications.

Martin gives insights: “Though for trucks, the gear ratios are longer and there is more slippage, hence ceramic clutches work better than organic clutches because the organic ones can burn. With ceramic clutches, the slippage can be as long as is needed. And in tractors, it is all about increasing the horsepower.”

Talking about electrification, he shares: “Electrified power trains would be interesting for India. For one, if the last mile which is being served today by the likes of Tata Ace goes electric, it will bring a big relief in cutting pollution in cities, also this segment will be easy to electrify. If the infrastructure is coming in faster, then India as a market can benefit much by electrification in daily use. And in the business cases of the entrepreneurs using SCVs and even electrified rickshaws, they can make use of our product range such as high-performance full battery packs and thermal management for batteries, separators of high voltage currents, and others. We can bring in the highest level of technology for efficiency to the market. And we will observe the market panning out in this context closely.”

A Winning Strategy

Miba’s advantage is that it has the ability to understand system applications.

Martin agrees: “We understand because all the components which we offer are made utilizing the knowledge about how a full system works. Our knowledge puts us in the position to understand the demands of the customer, the problems they need solved, and how we can add value to their performance. And this is now being translated into the solutions we are working for electrification. Our functionally-critical parts like for example, cooling solutions for battery, resistors and fuses in the S-box, we can bring it all to the table.”

If Miba grew by over 300% in India in the last decade, the officials are confident of doubling their growth by 2030. With a solid strategy, consistent robust investments and long, all-inclusive vision in place, the future of Miba’s growth story in India is looking strong and vibrant!