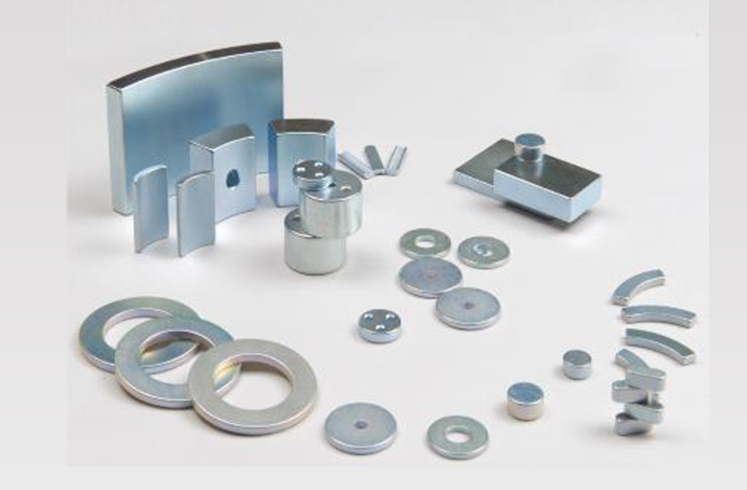

Innuovo Magnetics not only delivers its technical products in neodymium magnets according to print specifications but also provides technical back-up for customers from India

Permanent magnets in automotive applications have been in existence for several decades but common users of two, three, and four-wheelers have not been familiar with it as magnets are deeply positioned inside the application system and operate efficiently and silently. Neither trade journals nor technical journals have been devoting much space for such a commodity until probably the emergence of electric vehicles (EVs) on the Indian scene where battery technology and magnets are gaining prominence. Besides, the manufacturing technology of magnets has been considered as ‘proprietary’ in nature.

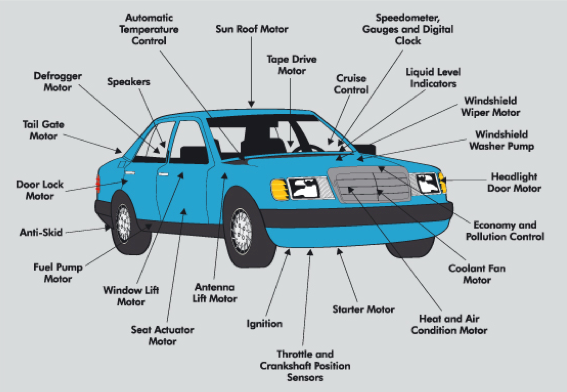

Wipers, blowers, window lifts, air-conditioners, door locks, windshield washers, starters, engine cooling pumps, sun roof motors are just a few of the motors in a car powered by magnets while in a two-wheeler there are generators and starter motors. A high-end car may have even up to 70-80 permanent magnet (PM) motors, besides several magnet-based sensors as part of sensory systems. In short, a person sitting in a car is practically surrounded by magnets. Magnets enable efficiency improvement and contribute to comfort as well as safety features.

While a four-wheeler may have several magnetic applications in one vehicle, for the Indian situation the usage of magnets in automotives is largely dictated by two and three-wheeler vehicles – about 20+ million produced per year. Traditionally, sintered ceramic magnets or generally termed ferrite magnets are most widely used permanent magnets in these applications, being cost-efficient material. The basic raw material in these magnets is iron oxide and strontium to formulate strontium ferrite which is shaped by powder metallurgy route under a high orientation field, sintered, and then precisely ground.

Transition

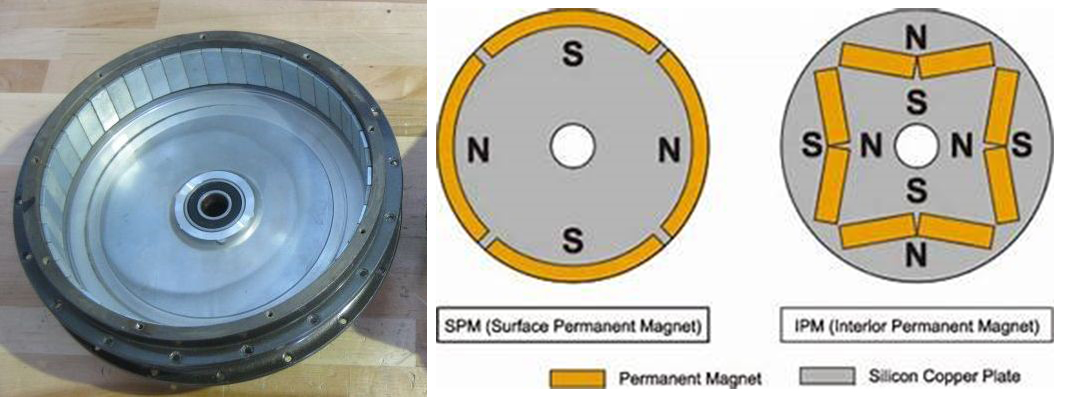

With significant changes in pollution norms to BS-VI standard, two-wheeler generator systems necessitated a relook to push up electrical output and hence magnets needed upgrading to generate higher output from the same size. With another change from April 2022, further effect may be expected. With changes in safety standards, fuel efficiency and onboard management system, more sensory systems are necessitated. To meet CAFE standards, most OEMs will need to introduce EV to meet the overall norms and hence a rush towards electric vehicles is expected. With EV, magnets have become an essential critical component of the ‘new engine’ –namely the traction motor. Hence, its gaining prominence is similar to battery since its implication in terms of efficiency is large.

All this means pushing ferrite magnets to higher grades such as doped grades (rare earth doped) and prominent use of sintered rare earth neodymium iron boron magnets is an inevitable change. As of now, on a commercial production basis, neodymium magnets are the most powerful magnetic material in use. While many Indian customers or users are familiar with ferrite design and systems, many are new to rare earth magnet systems as well as unfamiliar with how best to specify choices, design for best cost efficiency, and such considerations.

Innuovo Magnetics not only delivers its technical products in neodymium magnets according to print specifications but also provides technical back-up for customers from India. It’s a fact that at this point China is the world’s largest factory of neodymium magnets with leadership in ore extraction and purification process and thereby also magnet manufacturing. Innuovo Magnetics, belonging to the reputed Hengdian Group, is a public-listed-enterprise in China operating in neodymium since the year 1986, which marked the beginning of its usage.

Technological Leadership

Sintered neodymium magnets are made using rare metals such as praseodymium, neodymium, dysprosium and terbium and involve a long metallurgical process stream post metal or alloys to give reliable products with consistency on a mass scale. Hence, Innuovo Magnetics has installed a state-of-the-art manufacturing process with the latest equipment. Backed by its research and development centre and investing in and upgrading its production facilities, Innuovo Magnetics has been retaining its technological edge. The manufacturing line starts with strip casting for optimizing casting strip structure followed by hydrogen depreciation and grain size refining to improve particle size.

The subsequent process uses powder metallurgy route. The grain size control is ensured critically for strong magnetization orientation as well as to optimize heavy rare earth usage. Pressing into shape under a high magnetic field and inert atmosphere to give best orientation, hydraulic pressure to increase density and then a long sintering cycle under inert atmosphere is a much needed part of operational excellence exercised by Innuovo Magnetics for control of properties in a narrow band on a mass scale. State-of-the-art multi wire-cutting with extremely thin wires reduces wastages in cutting. The entire manufacturing is governed by strict process control and standard operating processes.

Unique Partnership

Innuvo Magnetics understands the needs of Indian customers with many of them being MSMEs. Start-ups desirous to develop motors using such magnets look for strong technical support locally. Hence Innuovo Magnetics is represented by a technical person of more than 30 years of experience in magnets in India which enables technical and technological dialogue and communication and support, understanding of matters, local and practical guidance, solutions to shorten the development cycle and reduce iterations and any such matters vital to the customers.

This is supported by a research and development centre and application backend team of engineers as well as test facilities. Innuovo Magnetics holds IATF 16949 and such international quality systems certifications and hence is familiar with expectations by automotive customers. In fact, the company’s strong research and development centre is working and researching on new high grades, expanding temperature range and process improvement such as grain boundary diffusion to bring down cost as part of this continuous improvement.

Salient Factors

- 35 years of manufacturing experience for neodymium.

- 6,500 tons of capacity and among 1st rank manufacturers.

- Four joint research labs and experimental production lines built together with academic society.

- Public listed company with strong financial background.

- Highly experienced India-based technical and commercial support.